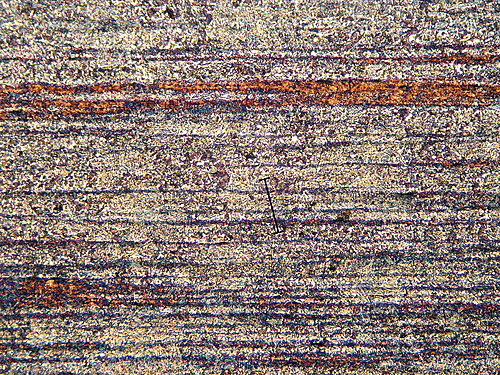

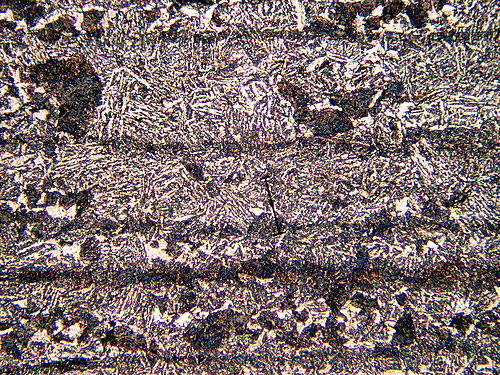

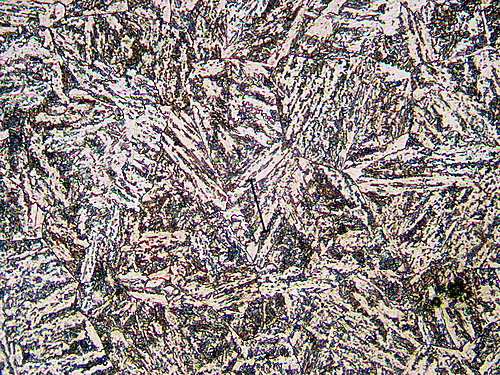

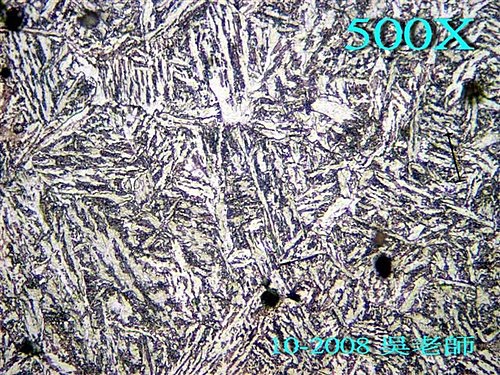

Real thing:4140 quench quenched to fully martensitic (HRC should be >58) and high-temp. tempered to HRC 30 +/- 5 to obtain highest toughness. Since bringing down hardness from 58~60 to 25~35 HRC requires a lot of heat energy (cost). Fake stuff appeared: Cool the as-rolled 4140 steel bar with forced air or water-mist to obtain the hardness of 25+ HRC. Their microstrctures are shown below. They may have the correct hardness, but since the microstructure are not correct. So their toughness will not meet the requirement. Buyers of auto parts be aware of this fact and do not get cheated by those Mr. Smart who sell you parts with fake Q/T process.

調質是先將鋼淬火成"全麻田散鐵"(fully martensitic)組織~HRC55 然後用高溫回火將硬度降至HRC 25~35 以取得最大韌性與強度之組合. 由於組織均勻, 真調質金相顏色一致.不會有上圖中的白色區域(肥粒鉄)出現. 調質成本很高, 有些聰明(or 奸巧?)的鋼廠, 在鋼軋延後噴水霧急冷, 得到如照片中"惠德曼肥粒鐵與微細波來鐵的組織, 也能獲得接近HRC30的硬度, 然後聲稱為"調質". 有內行欺騙外行之嫌疑. 這樣的組織, 晶粒粗大, 韌性遠比不上"真調質". 另外其 殘留應力也大, 需先消除應力後再加工 否則感應 淬火極易變形 淬裂. 有許多熱處理廠都吃過這種虧. 這相片就是一熱處理廠請我檢驗 然後拿著我的報告去教育客戶的. 他說他說的客戶不信 要"老師"說的才相信 所以他寧可自己掏腰包來讓客戶"長知識"

50X

50X 100X

100X 500x at 12x8 cm

500x at 12x8 cm

留言列表

留言列表