目前分類:熱處理_鋼 (228)

- Feb 09 Sat 2013 13:47

殘留沃斯田鉄---- 是敵?是友?

- Aug 01 Wed 2012 17:50

鑄鉄高週波淬火 波來鉄%要夠多

- Jul 17 Tue 2012 23:56

調質淬火後均勻的麻田散鉄組織

- Jul 11 Wed 2012 22:03

這種調質組織, 真夭壽!

JIS S55C; Darn lousy Q/T microstructure. Mostly fine Pearlite rather than T.M. required by Q/T. Insufficient Austenization time (leads to) → tiny grain size → poor hardenability → fine Pearlite. Also, oil-quenching was a wrong choice. This AISI 1055 should have been quenched using water-based quenchant to obtained enough amount of Martensite with ease. Quenching severity of oil is not good enough for 1055 to harden successfully.

- Jun 23 Sat 2012 16:12

淬後硬度 vs. C% vs. 麻田散鉄%

- Mar 03 Sat 2012 23:07

球铁曲轴 感应淬火/磨削 裂纹 废品堆积如山!

- Jun 20 Mon 2011 10:20

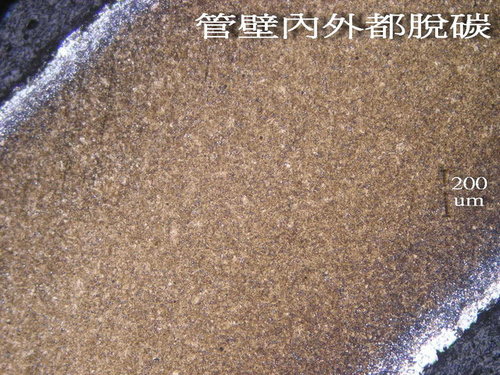

SK 5 淬不硬 W1, De-Carbed

- May 15 Sun 2011 17:34

高碳 Martensite

- Apr 17 Sun 2011 12:35

麻田散鉄 粗大問題 與微裂

- Mar 23 Wed 2011 08:47

細粒鋼

1513Cr Steel with very fine grains. Photo A: Q/T. Tempered Martensite. Photo B and C: Martensite islands in Ferrite matrix obtained by induction heating to subcritical region(between A3 and A1) and air cooled.

- Mar 14 Mon 2011 10:05

球粒化退火 spheroidization annealing

照片 1 ~ 4, 7 : 暗視野照明. 發亮光奌為球粒碳化物. Photo 1 ~ 4, 7, dark field . Shining particles are spheroidized carbides---a must-have for good forgeability. 這是為冷鍛工作所做的"前置"處理. 波來鉄不做球粒化, 冷鍛時易生裂紋---micro & macro.

- Jan 10 Mon 2011 18:59

鑄鍛塊金相組織的比較

- Dec 01 Wed 2010 06:48

晶界上的壞東西--碳化物

- Oct 17 Sun 2010 20:45

帶狀偏析 banded segregation

- Oct 17 Sun 2010 20:32

1045 annealed

- Jun 17 Thu 2010 19:39

鉄絲/鉄片 金相 iron wire / sheet

碳素%超低 < 0.08%, 故幾乎全部是 肥粒鉄. 紅箭頭所指為晶界上的碳化物. Extra-low carbon steel sheet for forming. Microstructure is mostly Ferritic with traces of Carbide particles---arrowed.

- May 03 Mon 2010 22:49

鏡面 真空氣淬後 A quenched mirror surface

肉眼看來, 表面仍維持光亮, 但在顯微鏡下 出現此浮凸圖案. (相變化引起) (SNCM 440)