目前分類:熱處理_鋼 (228)

- Apr 03 Fri 2015 21:36

SNCM 440 淬後as_quenched

- Apr 02 Thu 2015 10:19

S45C 正常組織

- Feb 27 Fri 2015 22:37

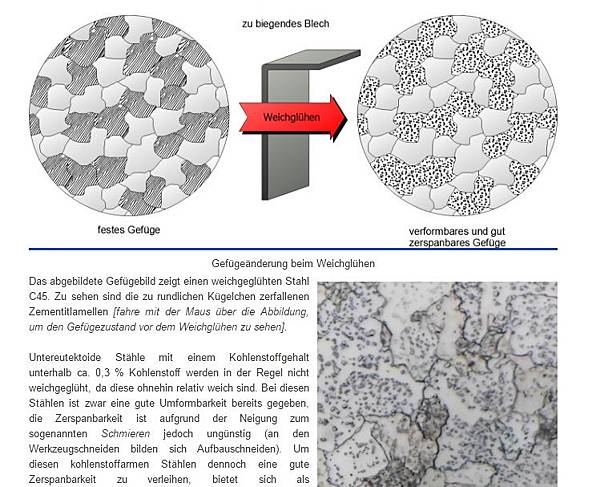

鋼的 球化組織

- Feb 23 Mon 2015 18:55

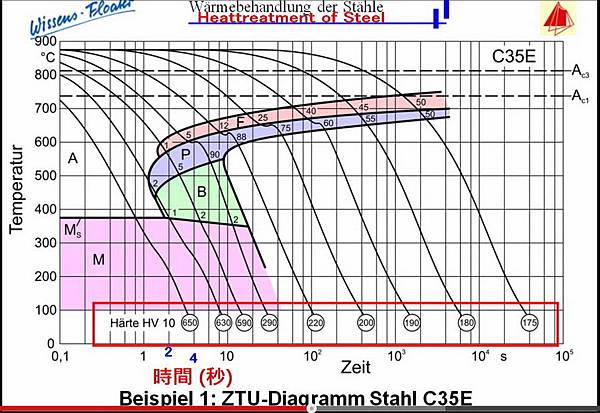

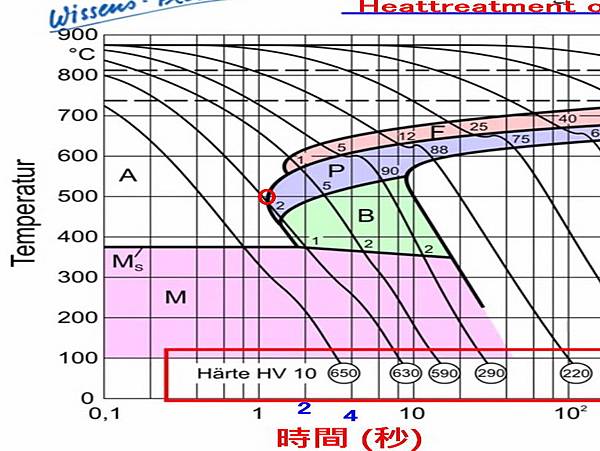

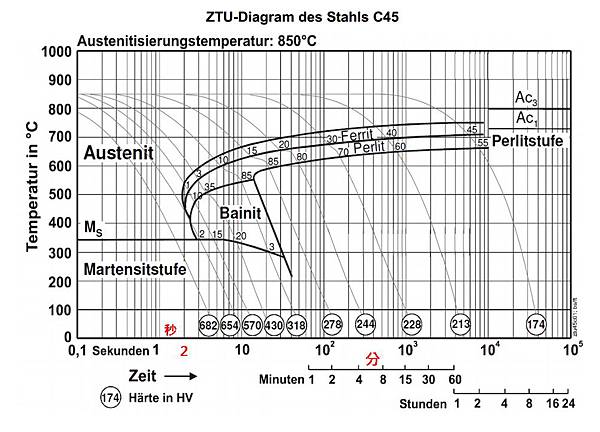

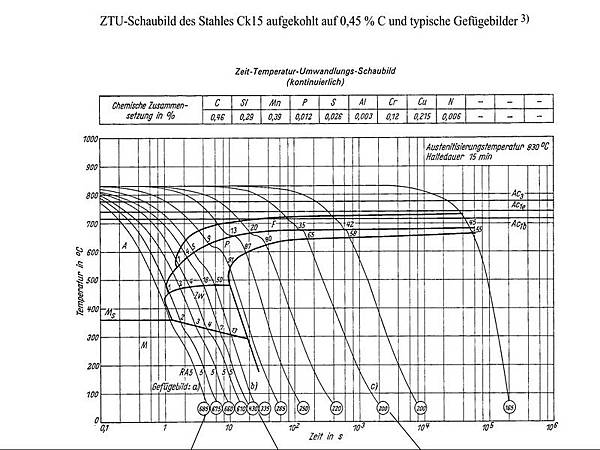

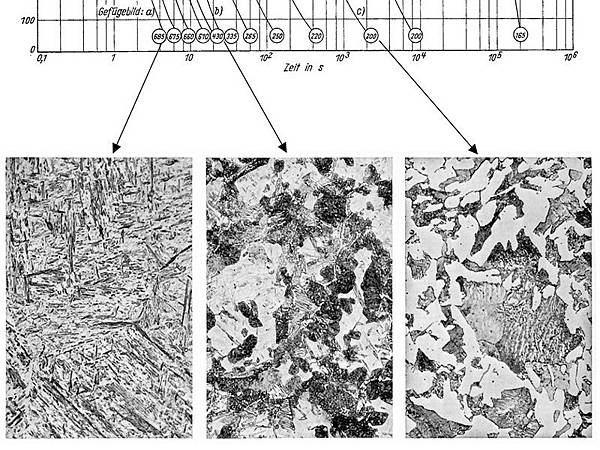

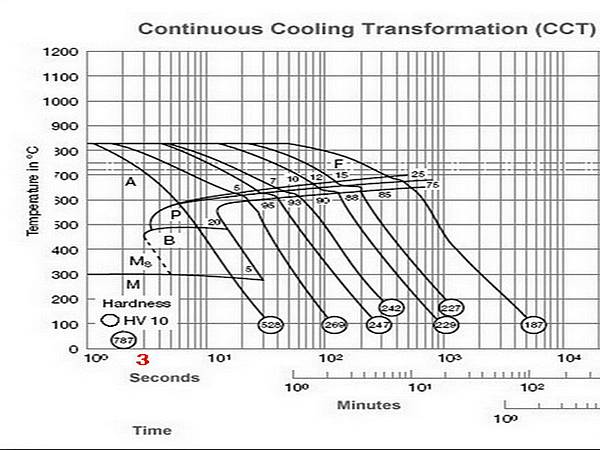

連續冷卻 35C, 45C, 60C

不含合金元素的普通碳鋼 35C, 45C, 60C 被歸類為水淬钢. 通常需淬水才能得到全Martensite的. 油冷不易得全M. 不得全M, 強度就大打折扣. 注意這三種鋼 波來鼻端時間分別是1,2, 3秒. 也就是說要在此時間內降到500C, 才能不出現F,P,B等非M組織. 調質熱處理必須有>95%的M, 再經高溫回火 才算正確. 熱處理廠水淬鋼用油淬的調質, 其實都是騙外行人的作法.

- Feb 22 Sun 2015 18:26

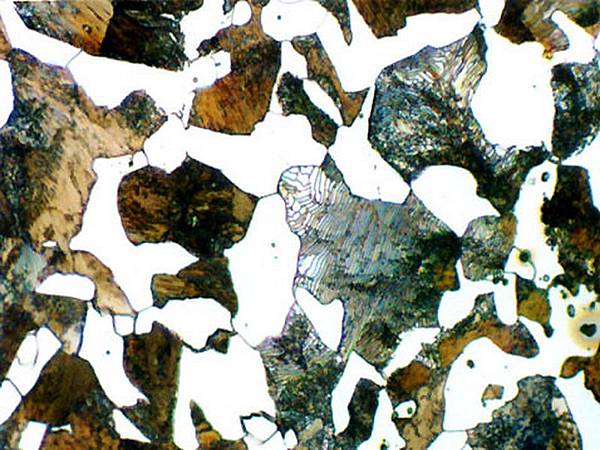

金相照片 欣賞

- Jan 26 Mon 2015 10:40

水泥鋼釘 金相

- Dec 24 Wed 2014 18:45

S45C Jominny test 前端淬水

- Dec 20 Sat 2014 06:34

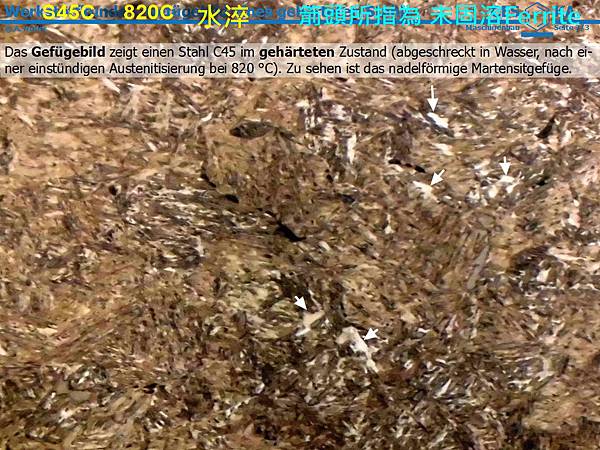

S45C 熱履歷 vs 金相

- Sep 28 Sun 2014 21:51

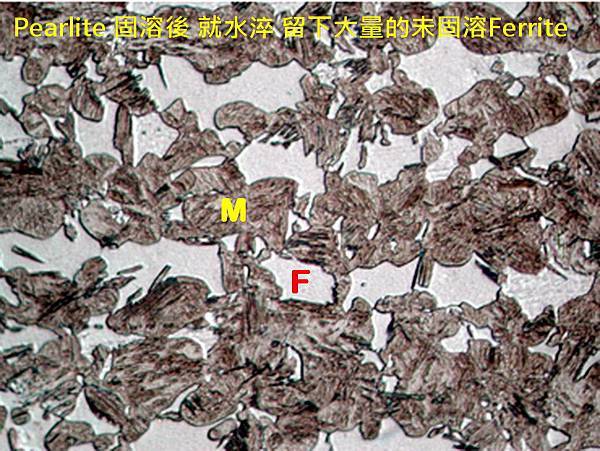

45C 半固溶的 碳化物

- Sep 07 Sun 2014 15:21

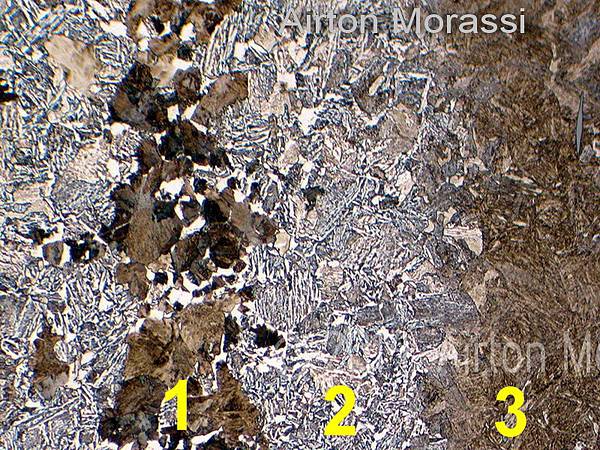

Mixed Microstructures 雜亂的金相組織

縱剖面: 上: 1, solute-poor; 3, solute-rich; solute指 carbon & alloying elements, like Mn, Cr, ... 溶質指 碳/合金 的濃度.

- Sep 03 Wed 2014 09:29

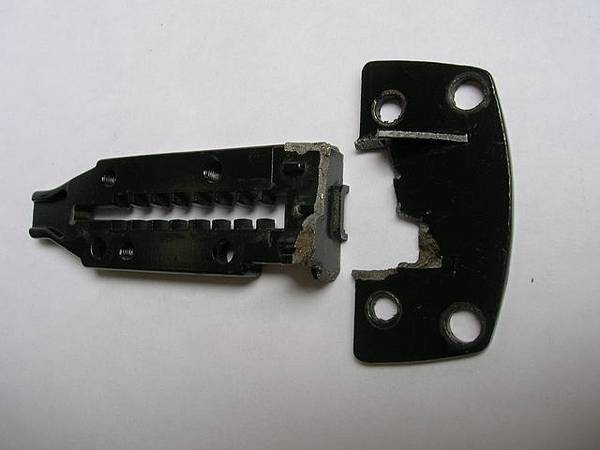

45C 油淬組織

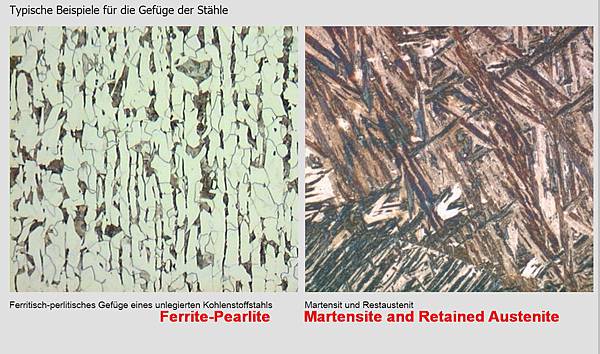

S45C是水淬鋼. 用油淬得"非麻組織"(F+P+B)的機率太高了. 相片中 顏色較暗的都是波來鐵P. 白色是初析肥粒鐵F. TM:Tempered Martensite, 回火麻田散鉄. 調質所希望獲得的組織. 在此之前所出現的都是"非M組織".

- Aug 28 Thu 2014 10:55

鋼的正常化熱處理 Normalizing

- Aug 10 Sun 2014 18:25

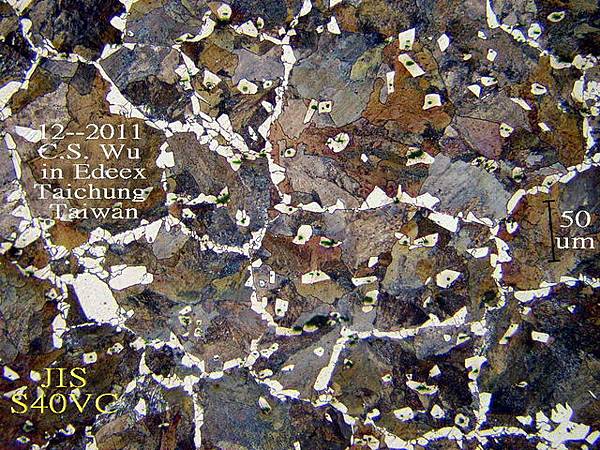

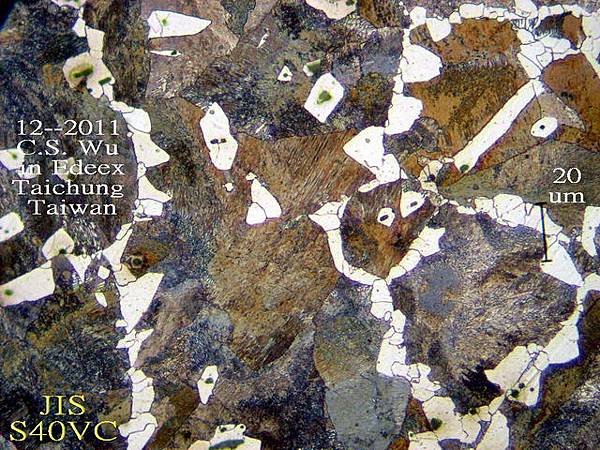

Microalloyed Steel, JIS S40VC

- Jul 02 Tue 2013 17:08

晶界上的壞東西--碳化物

- May 17 Fri 2013 22:33

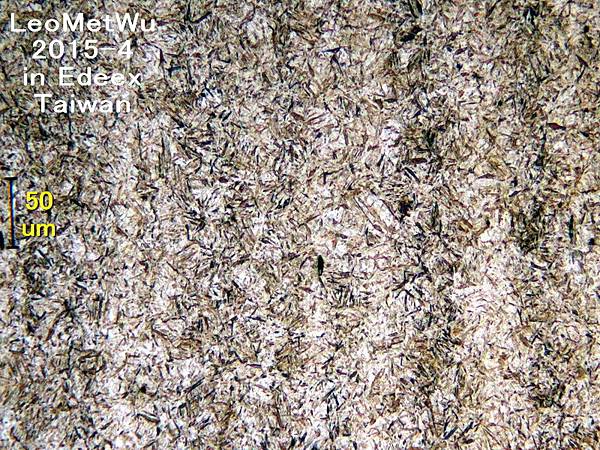

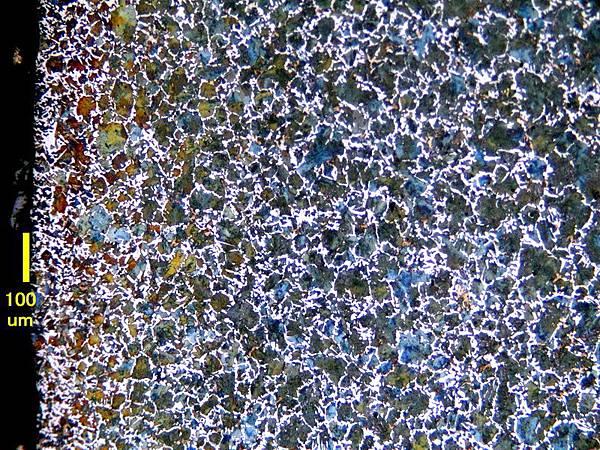

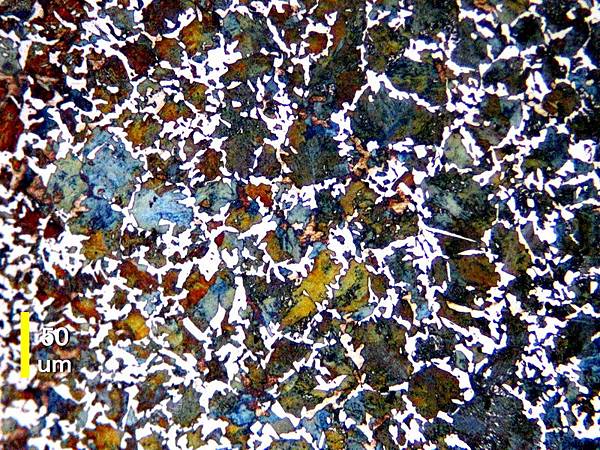

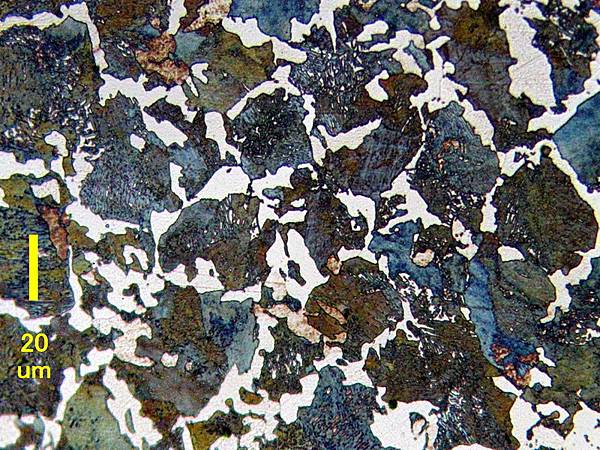

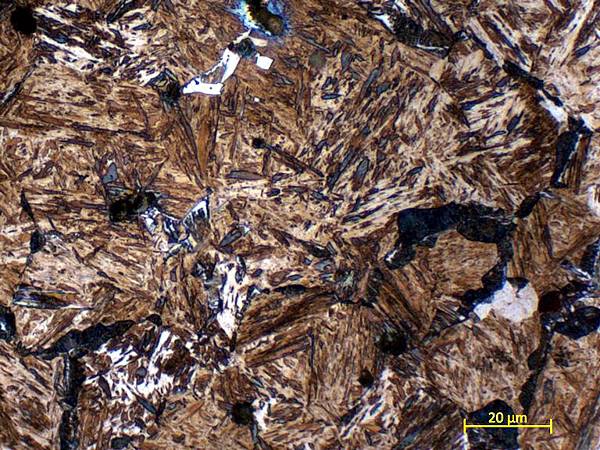

AISI 4140 over-heated; SCM 440 感應過熱

紅十字, JIS SCM440, induction hardened. Corner locally over-heated, coarse grains obtained and workpiece cracked on quenching. These beautiful photos of Martensite are obtained by color etching, with a bit of luck and lots of labor. If you look closely, you will find grain diameter is the largest at the bottom of the photo because it is the edge of a hole where induction heat concentrates. Crack is not shown here but it initiated from the corner of the hole. At the bottom, grain diameter is about 50~90 um which is too coarse, therefore workpiece cracks readily on quenching.

- Mar 22 Fri 2013 18:18

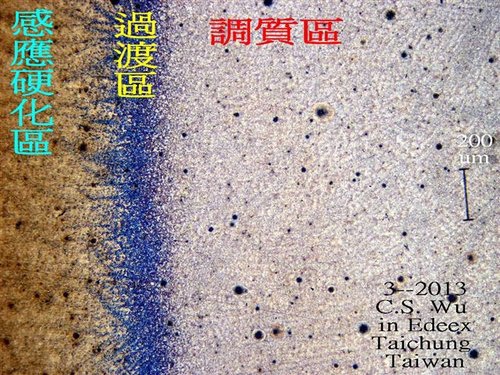

S45C 調質金相