- Aug 18 Sat 2007 11:56

灰白鑄鐵共存區

- Aug 17 Fri 2007 15:31

Quench crack 鏈(條)片淬裂

- Aug 14 Tue 2007 22:22

球粒化退火後的 AISI 4140

- Aug 14 Tue 2007 22:01

素材 晶界碳化物 SKD 11

A JIS SKD 11 (DIN 1.2379) tooling was submitted to check the cause of the crack, initiating from the sharp key groove. I was told that this tooling cracked under a single blow of a hand hammer. Coarse, grainboundary carbide (GBK) network is clearly seen at 100X. It was left from a faulty material. These GBK formed after forging of an ingot. Note the parallel twin boundary carbide. SEM photo shows the flat surfaces of twin boundaries. Inspected in 1984 in MIDC. 1984 我於台中金屬中心擔任 破損分析/金相檢驗 工作所攝.

簡述: 送驗者說他使用前 習慣性用手鎚敲一下, 就從鍵槽底裂開了. 故送驗以了解: 是材料或熱處理出問題, 為何如此不堪一敲?

- Aug 13 Mon 2007 23:26

衝床濕式離合器片 clutch plate

- Aug 13 Mon 2007 19:36

假調質的 SCM 440 Fake Q/T

Real thing:4140 quench quenched to fully martensitic (HRC should be >58) and high-temp. tempered to HRC 30 +/- 5 to obtain highest toughness. Since bringing down hardness from 58~60 to 25~35 HRC requires a lot of heat energy (cost). Fake stuff appeared: Cool the as-rolled 4140 steel bar with forced air or water-mist to obtain the hardness of 25+ HRC. Their microstrctures are shown below. They may have the correct hardness, but since the microstructure are not correct. So their toughness will not meet the requirement. Buyers of auto parts be aware of this fact and do not get cheated by those Mr. Smart who sell you parts with fake Q/T process.

- Aug 13 Mon 2007 19:04

夭壽的鍛模 2344 / SKD 61

- Aug 13 Mon 2007 18:43

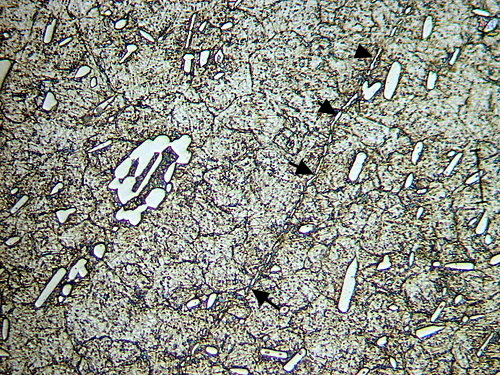

素材不良 SKD 11, DIN 2379

上: 500x; 下: 100x at 12x8 cm; 下圖中看到的晶界是素材的"原沃斯田鐵晶界"(prior austenite grainboundary) 非常粗大. 碳化物形狀與分佈也不正常, 在500x下, 上圖中間稍偏右 呈45度 由右上往左下, 中有斷斷續續碳化物薄膜之晶界,為素材的晶界. 其他較細的晶界(黑線)則為後來淬火加熱所產生的晶界. 這樣的金相, 韌性極差. 模具一定短命. 但往往是熱處理者背黑鍋, 因為1. 要顯現出此金相 需有一點功力 熱處理廠QC人員 鮮有此功力 2. 材料商所聘的"門神"或許有此功力 但縱使看到這樣的組織, 也會把破裂原因轉移到別處.

上: 500x; 下: 100x at 12x8 cm; 下圖中看到的晶界是素材的"原沃斯田鐵晶界"(prior austenite grainboundary) 非常粗大. 碳化物形狀與分佈也不正常, 在500x下, 上圖中間稍偏右 呈45度 由右上往左下, 中有斷斷續續碳化物薄膜之晶界,為素材的晶界. 其他較細的晶界(黑線)則為後來淬火加熱所產生的晶界. 這樣的金相, 韌性極差. 模具一定短命. 但往往是熱處理者背黑鍋, 因為1. 要顯現出此金相 需有一點功力 熱處理廠QC人員 鮮有此功力 2. 材料商所聘的"門神"或許有此功力 但縱使看到這樣的組織, 也會把破裂原因轉移到別處.

- Aug 13 Mon 2007 16:59

不銹鋼粒界腐蝕

200 x, 200x, 1000x at 12x8 cm; 經鏡面拋光的不銹鋼塑膠射出成形模具(大立光電的), 粒界腐蝕源自冷卻水孔, 致使昂貴的模具夭壽. Micrograph of a prematurely failed plastic injection tooling made of stainless steel. Grainboundary corrosion cracks initiated from inner wall of cooling conduits. Multiple, branched cracks is usually SCC----Stress Corrosion Cracking.

- Aug 12 Sun 2007 16:01

CCT 鋼 連續冷卻

50X

50X